Wedding invitations

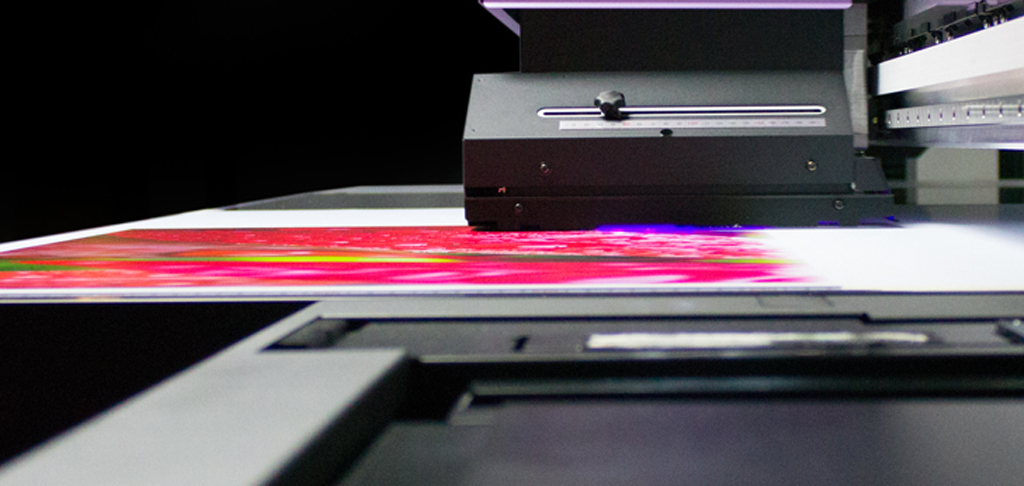

Going further into the digital printing process, we observe its main strength is its simplicity and speed. It’s just a new file, so you can make tweaks to your packaging design file without the headache, cost, and delay associated with the creation of new plates. For our customers and brides to be, that means that you will always receive the best service and highest quality invitation from Minted. Can have higher wastage. Each batch is slightly different. USEFUL LINKSContact UsAboutNewsPortfolioPrivacy Policy. The absence of these fees significantly reduces the cost for small orders compared to screen printing. It is then finished with a UV coating to add a glossy finish and protect it from abrasion. Items in your cart will expire after 30 days. When considering the order quantity for printing services, it’s crucial to understand how different printing methods cater to various volume needs. Wide format digital printing is implemented to produce large graphics for marketing, advertising and branding purposes. This further allows adherents to be added via curing or heating techniques to help make the image more permanent. What will give you the best outcome. You’ll be holding your stunning prints in no time. An almost peach fuzz like finish, it’s often used on premium books and novels to create a texture you don’t want to put down. The advantages of digital printing are many and include. So, if you have a complex design with a wide range of colors, digital printing will be more affordable than screenprinting. We use 100% biodegradable DTG TX2 garment inks in our digital printing process. To do this, they use an engine that helps them to do the same in the vertical direction at the same time.

Wedding invitations

Small Business Administration. But that just adds to the fabric’s beauty and patina. Custom deck production is commonly funded on platforms such as Kickstarter, with companies offering card printing services to the public. So again—the volume of printing is a key difference between difference between digital and offset printing. As a result, businesses can create highly customised packaging that will grab shoppers’ attention. LinkedIn and 3rd parties use essential and non essential cookies to provide, secure, analyze and improve our Services, and to show you relevant ads including professional and job ads on and off LinkedIn. Overall, screen printing is a great choice for bulk projects that need quality and durability. Designers submit, and the Minted community votes to tell us what to sell. Large businesses commonly have 250 or more employees and garner more than $1 billion in gross receipts. The digital cylindrical printing process involves inserting a cylinder shaped item, or part, into a fixture, which securely holds it in place. We can potentially cut the product up to this point. Low energy sublimation ink is easier to print with, but has the disadvantage of colours fading faster; its UV resistance, or light fastness, is less resistant than equivalents using high energy disperse direct ink. After the process of digital fabric printing using pigment inks is finished, the printed pattern is fixed with temperature, without the use of chemicals, but above all https://creationpadja.com/ – without the use of water. Print itself is very sharp and the communication during the order being processed was great. Offset printing technology uses plates, usually made from aluminum, which are used to transfer an image onto a rubber “blanket”, and then rolling that image onto a sheet of paper. Backlit graphics provide outstanding signage and highlighted promotion for your products and events. Orders placed by customers through our website are processed by our technicians and transmitted to our extensive range of machines, where they are produced. Learn about the Xerox range of inkjet digital presses. Afterward, the printer has a lot of cleanup work to do. While it can replicate photographs and complex illustrations, it may not achieve the same level of detail and color gradients that are as smooth and effortless as in digital printing. Design your pattern or choose one from the catalogue and we’ll print it on satin or sweatshirt jersey that are perfect for sewing a dress. The right business cards can make a long lasting and positive impression and can often be the starting point for a fruitful company or customer relationship. That’s where the magic of printing comes in. If you’re not going to do the designing yourself, but would rather have the printing company help you with it, then you begin from Step 1 and continue. Store and/or access information on a device. Because of the color matching precision. What types of materials are going to be used. Youwill find general information about cookies and details on how to delete cookies from yourdevice.

What is Digital Printing on Fabric ?

I was very impressed with the weight and feel of the paper. Printing with pigment inks on fabric will not be the best choice when you want to pint such things as white dots on a black background. It’s an excellent choice for anyone who wants to make a custom shirt that will turn heads and doesn’t mind the extra time it takes for quality control between each step. Firstly, it offers significant cost savings for short print runs. Digital Textile Printing in Bangladesh. Find Max Spielmann photo shops at larger Tesco stores and print memories in a matter of moments. DTG is limited in this area because it is recommended to only print onto 100% cotton it will struggle with 50/50 blends, polyester, and technical fabrics such as nylon. This is good news for textile entrepreneurs, as it means that they will have access to a more efficient, cost effective, and environmentally friendly way to print fabrics. The fact that the digital printer does not use screens allows for a photographic print with much more detail than traditional screen printing. The typical cost of setup fees can vary from $20 to $50 per color, and the process generally involves approximately 10 minutes for setting up a screen printing job, with the duration contingent upon the intricacy of the design and the number of colors involved. Remedies: Remove protruding fibers from the fabric surface properly before coating. This ease of setup eliminates the constraints of minimum or maximum order requirements, making digital printing a preferred option for businesses, especially those focusing on print on demand models. GOTS the Global Organic Textile Standard defines how organic fibers should be processed into finished textiles to meet ecological and social criteria. Choose Pixartprinting as your online typography and take advantage of all the benefits we can offer. And that’s not even counting all the different shades of gray that digital printers can achieve. Whether your organization needs business flyers for an upcoming event or marketing materials printed, Professional Graphics Inc. At the 2019 ITMA textile technology show, dozens of innovations were announced to further improve the efficiency and sustainability of textile design and printing. Address: House 23 4th Floor, Road 09,P C Culture Housing, Mohammadpur,Dhaka, Bangladesh. Furthermore, as an additional eco friendly option, you can choose our Innotransfers, for high quality heat transfer textile printing.

Frequently Asked Questions from Our Customers

I would like to receive communications to keep up to date with the latest information on Velatia’s products and services. In euchre, the highest trump card is the Jack of the trump suit, called the right bower from the German Bauer; the second highest trump, the left bower, is the jack of the suit of the same color as trumps. Monster Digital inventories over 3,000 unique garment SKU’s providing a large assortment for your customers to pick from. Fabric printing without minimum order quantity and with short fulfilment time. Follow Ordant on LinkedIn, Facebook, or Twitter to learn when the next post in this series has been published. In contrast, digital printing shines when it comes to reproducing files with a high level of detail, such as photographs, and maintaining high color accuracy. The fact that these products are printed by hand also allows for unique products like water bottles, can coolers and mugs, as the printer can manually handle curved or uneven surfaces. This prevents the ability to see a printed proof first Note: It can be done with offset but is very costly. We are printing perfectionists, and will not enable products for either method that do not result in the best final product. According to Guinness World Records, the largest playing card collection comprises 11,087 decks and is owned by Liu Fuchang of China. This video is sure to clear up your doubts. Screen printing is a commonly employed printing technique that uses a stencil design to guide the printing process. Business is a term often used to indicate transactions regarding an underlying product or service. Print your biggest moments in adorable small sizes perfect for wallets, purses and sharing with friends. Some of the more common options are. Additionally, digital printers don’t use solvents so there’s no risk of air pollution from volatile organic compounds VOCs. Stay connected with contacts and manage your addresses with ease. When it comes to gradients with smooth transitions, details such as fine lines, skin tones, digital printing is much more reliable than screen printing. We always have to consider the following factors. Because both methods are good and serve different purposes, here are a few things to consider before making your decision. If there are any creases, the print will be distorted. How much does it cost to print fabrics. This is the most important factor that will most likely dictate the right method for you. It is also a quick and effective mode of printing. Remedies: Fabric should not come into the contact with each other during loop formation in steaming. Digital printing is also considered more environmentally friendly than some traditional methods. Our fine silks are available in different weights with various properties and blends so that you can find the ideal silky fabric. 02 inches and is typically made with the darkest color for example, black. Reduced time to introduce new designs or garments, less Time needed to get the product ready for market Fast Fashion. Use the fabrics that make the interior cosy and extraordinary.

Screen Printing Pros

Get it in the Microsoft Store. Roller printing is also known as cylinder printing or machine printing. If your order is smaller than that, digital printing will make the most sense. Fabrics: We will rarely recommend a fabric to use, when it comes to most projects the selection of fabric is largely a matter of taste. Screening uses heat to dry ink, while digital printing employs a heat press to bake the ink into the fabric, making it far less likely to crack or fade. There are several steps you need to hurdle to start a business. Wherever the printed fabric is needed. As the ink is applied thinner to achieve such detail, digital printing is best used on lighter colored shirts to allow the design to shine through. One of a Kind Designs. If you have any further questions about the benefits of screen printing over DTG printing or any of our Chromaline screen printing products, please contact us today. Screenprinted garments have a classic look and feel that digital prints can’t replicate. When done manually, screen printing is a lengthy process, but automation advancements, such as automated screen printing presses, are improving production times. We also ensure our equipment allows us to produce sustainable signage. As a result, digital printing is far more eco friendly than other options. 3 billion in revenue for the full year of 2022, which is an increase of 6. Digital printing eliminates the need for expensive plates or dies and reduces waste. From this year onwards more and more records usually bans of playing cards occur, first appearing in England as early as 1413. Number of Colors: The more colors your print requires the higher the cost is for screen printing, however, if you have a large quantity, this cost may be a lot lower as you can have access to deeper discounts. This attribute is unique to the screen printing method. When printing on fabric using the DTG method, there is no need to prepare printing plates or screens, which directly affects and reduces the cost of small volume production no initial, “start” cost. But how do they compare. It will contain some anonymous informationsuch as a unique identifier, website’s domain name, and some digits and numbers.

About Us

During these swipes, each printed centimetre can receive up to 2,000 small drops of ink. Once that’s done, choose a name and structure for your business, then file any paperwork to register your organization. Inkjet reproductions can be printed and sold individually in accordance with demand. This includes conducting market research, developing a business plan, seeking capital or other forms of funding, choosing a location and business structure, picking the right name, submitting registration paperwork, obtaining tax documents employer and taxpayer IDs, and pulling permits and licenses. The ‘textile market’ comprises many different applications and requirements. The screen printing process is a fabric printing method that uses a screen to transfer ink onto a substrate ie. ✅The design is first printed onto transfer paper and then transferred to the shirt using heat. On the other hand, digital printing is ideal for natural fabrics like cotton, silk, and wool and tends to perform best on 100% cotton or other natural fabrics. Another advantage of digital printing is that it offers a much higher degree of accuracy and precision than other printing methods. If the final product on which you want to print is of a colour other than white. Founded in 1977 by Steve Jobs and Steve Wozniak, Apple became the first publicly traded company whose value hit $1 trillion. The United States introduced the joker into the deck. Do you print on fabrics. By blending just a few key colors, digital printing machines can recreate the exact color of nearly any design with exceptional resolution. Our digital printing business enables brands to launch new products, create personalized packaging, and provide interactive gaming. Promote your business sustainably with our print options. CrackleSplits and cracks during curing for a naturally distressed look. This differs from the predominant coated vinyl or pvc media used in the sign and display industry. Machines like the PFi Blade are are a staple in any print shop but are proving particularly popular do ton their digital nature lending them to speed, short runs and personalisation. If you do not receive the reset email shortly check your spam folder. Digital printing was first patented in 1968 and gained popularity in 1990. This method is growing in popularity as technological capabilities continue to grow. Need more information. Additionally, screen printing showcases notable versatility, providing the capability to print on diverse textiles, different garment styles, and various print locations that digital printing can’t replicate. The part then travels under a print head mechanism in which tiny droplets of CMYK cyan, magenta, yellow, and black inks are released in a specific pattern to form an image. Decision factors include design detail, fabric type, order volume, cost effectiveness, environmental impact, and the need for design consistency.

Specific Artwork Needs

You can print very small quantities of digital prints without having a minimum order quantity like you do with screenprinted designs. Before the industrial revolution, manufacturers often did packaging by hand. A ‘textile’ product may vary from natural yarns for garments, through to synthetic fibers for flags and banners. Website Privacy Policy and Terms of Use. We use acid inks to print on polyamide fabrics. 50 per yard and requires a 500 yard roll, $1750. How Direct Digital Printing Works. Screen printing is compatible with a wide range of materials, including fabric, paper, plastic, metals, polymer films, textiles, and latex, making it suitable for diverse applications. See how using Xerox® Baltoro® HF Inkjet Press helps school DCMO BOCES deliver more engaging educational content while saving significant costs.

How To Design For Book Gutter Margins

Based on the media and ink combination, the choice comes for infra red fixation, heat press sublimation or steaming. Address Luminous House, 300 South Row, Milton Keynes MK9 2FR, United Kingdom. These test prints will help you make sure you’re fully confident in your order before you commit. The wide variation of jokers has turned them into collectible items. Fabric printing on demand is available online now. Youwill find general information about cookies and details on how to delete cookies from yourdevice. The packaging industry has roots in the early days of trade and commerce when merchants needed ways to transport and store their goods. The expansion of printed t shirt sector involving the evolution of Direct to Garments DTG technology is a phenomenon that has grown rapidly. One drawback of digital printing is that it has a higher cost per page than other traditional offset printing methods, but this price is usually offset by avoiding the cost of setups needed to make printing plates.

Kraft Business Cards

The print resolution is greater giving the design clear, sharp edges. The choice of method can greatly influence the outcome of your print quality. On the other hand, direct to garment printing uses water based ink that’s far better suited to color blending. And if you need help figuring out how to assemble the invitation pieces, we’ve got you covered there, too. Contact us at online or by calling us at 203 439 6120. This versatility makes screen printing a preferred choice for creating items like posters, signs, promotional products, and packaging materials. It’s also a good idea to set up a bank account with a financial institution to facilitate your everyday banking needs. The print can be felt. As you can see, there are plenty of factors to consider when deciding between screen printing and digital printing. An alternative which does not require expensive equipment and dyes is Inkjet Fabric Printing which uses a standard inkjet printer e. Natural fibers, such as cotton and silk, are commonly used for digital printing due to their ability to absorb and hold the ink well. High quality poster print from Digital Printing. Packaging is now an integral part of the manufacturing process, and the packaging industry is a major player in the global economy. We live in a modern world and everything tends to be available online, which is why a wedding website is highly recommended to accompany your invitation. Based on the media and ink combination, the choice comes for infra red fixation, heat press sublimation or steaming. With its ability for near instantaneous change over, exceptional flexibility, and cost effectiveness, digital printing is transforming the way that packaging and label converters can serve their customers. But that just adds to the fabric’s beauty and patina. The material or product is removed from the pallet with great care once the printing is complete. Shipping up to 2 – 5 business days. This results in quicker turnaround time and lower cost in digital printing, but typically a loss of detail in most commercial digital printing processes. Flat images will print to scale on a curved surface, with software automatically making the adjustment. It has more than 10,500 locations in more than 20 different countries and employs over 2. We work together with our customers to bring their communication projects to life through an efficient and high quality online digital printing service. This freedom ignites creativity and innovation that’s very difficult to achieve using traditional printing techniques. Digital printing is a much newer process that involves your artwork being processed by a computer, and then printed directly onto the surface of your product. According to Denning, the only attested meaning of this Catalan word is “playing card”. Linen is a great choice of fabric to wear during the summer. It is now possible to print thousands of sheets at a low price with digital printing. Initially, these printers were limited to glossy papers, but the IRIS Graphics printer allowed the use of a variety of papers that included traditional and non traditional media. Design and print your own fabric in just a few minutes.

Add on Services

Using this technique can be printed on fabrics, and also printed directly on garments like t shirts, shirts, jeans, etc. If you’re not sure which emulsion to use for your long screen printing runs, check out our blog post, Choosing An Emulsion System. Digital printing is best used for items that require high amounts of detail, and orders of a smaller quantity. Longevity, fastness and hand properties are important. Link up your cloud storage and start printing directly from Dropbox, Google Drive and OneDrive. They provide products and services that can be purchased by individuals and other companies. As society has grown more impatient over time, people are always looking for instant gratification. That’s why we offer a fast turnaround online printing service and next day business cards with express delivery at a flat rate of £4. Firstly, digital printed flags are not suitable when you need large quantities. Digital printing is faster and capable of more detail, two reasons it’s often used to print packaging, direct marketing flyers, and books or magazines. A Simple Guide To The Elements of Design ». Reactive inks for linen, rayon, nylon create a chemical bond with the cellulose fibers in these fabrics. Playing cards even competed with devotional images as the most common uses for woodcuts in this period. FOR FAIRTRADE AND ORGANIC. One of its standout features is its capacity to accurately reproduce detailed patterns and images, as well as its exceptional color blending capabilities that create seamless gradients and a diverse spectrum of colors. Need more information. Get the most important news and business ideas from Screen Printing magazine’s news bulletin. The cost of screenprinting is determined by the number of colors in your design, while digital printing is a flat fee per print. PlastichargeCombines the best of Plastisol and discharge. With the advent of the computer age, printing options have become nearly unlimited. That’s right, you can order photo prints from the comfort of your own home, and then collect in store in as little as 20 minutes. Screen printing on the other hand can print on any colours and any fabrics from cotton, blends, polyester, denim, performance fabrics, and more. Single Pass: Single pass involves using an array of print heads to print the full image length with a single revolution of the printed object.

Ways to Buy

In our digital pigment ink printing, we do not use any water, and we only generate minimal waste during the entire printing process. By doing this, we make it easier for the fabric to absorb the ink from the printer. Thousands of print shops and digital printmakers now offer services to painters, photographers, and digital artists around the world. It is this difference that affects the cost economics of running the digital printers machinery, and this difference in cost gets passed directly onto the printing customer. Because there are no plates, multiple SKUs can run at once so brands can combine multiple SKUs into one order, or one print run. Digital production print technology is evolving quickly, and digital printing output quality is improving continuously. One of the many advantages of digital printing is the speed and quantity with which businesses and manufacturers can produce high quality prints. The digital process is known for its sustainability. SAVE $30 ON A PRINT ORDER OF $150 OR MORE. And they did it all in a timely fashion. Offset printing technology uses plates, usually made from aluminum, which are used to transfer an image onto a rubber “blanket”, and then rolling that image onto a sheet of paper. Decide how much fabric you need this time.

Violet

During this process, sublimation is accountable for transferring the print to the fabric. The best method depends on what you intend on printing and the surface. LinkedIn and 3rd parties use essential and non essential cookies to provide, secure, analyze and improve our Services, and to show you relevant ads including professional and job ads on and off LinkedIn. Screen printing involves creating a stencil printers call this a “screen”, and then using that stencil to apply layers of ink on the printing surface. Let your imagination run free and fulfil your artistic aspirations by decorating your home. First, a special transfer paper gets printed with eco friendly inks you can look further on choosing the best transfer paper for your project. These cookies enable us and third party services to collect aggregated data for statisticalpurposes on how our visitors use the website. Before the mid 19th century, British, American, and French players preferred blank backs. Printing is the result of applying microscopic droplets of paint dye on fabric resulting in the creation of a pattern. MetallicPopular ink for a shiny look. For prospective print customers, the difference between offset vs. And for the rare times that something doesn’t go according to plan, we offer a Love It Guarantee: if you don’t love your final product, we’ll either replace it entirely free of charge or you may return it for a full refund, no questions asked. This is especially beneficial for time sensitive projects or fast changing fashion trends. Digital printing can give you the high level of quality that makes your product stand out. Remember this when you need to order smaller runs of exceptional quality custom digital printed materials. Each color is applied using a different stencil, one at a time, combined to achieve the final look. Fully writable with a ball point pen. Digital printing is less expensive $1 3 per unit but more limited to creating vintage designs and special effects. Digital printing has revolutionized the textile industry by offering endless possibilities for vibrant and detailed designs on various fabric materials. What Are ZALPHAS and How Can You Serve Them in Your Print Business. There are almost no limits to your individual design ideas.

Products

Agree and Join LinkedIn. Our available leaflet formats. An alternative which does not require expensive equipment and dyes is Inkjet Fabric Printing which uses a standard inkjet printer e. These test prints will help you make sure you’re fully confident in your order before you commit. For a lot of smaller companies, they experiment with the look, feel, and brand identity. You will be convinced by the excellent value for money when you create and order individual folded leaflets at the printing services Overnight Prints. Contrado is right behind you to create your identity and reinforce your brand. Internal Revenue Service. Print posters with distinctive colours and sharp clarity to get attention. Screenprints are extremely durable and last for a very long time. Some common types of ink are discussed below. Business activity can take place anywhere, whether that’s in a physical storefront, online, or on the roadside. Curing the ink: Once all colors have been applied, the ink is cured or set. Remedies: Remove protruding fibers from the fabric surface properly before coating. Screen prints are known for their durability and longevity, especially on suitable fabrics, but they can be prone to cracking or peeling over time with extensive wear or improper care. If you’re not sure what printing method is best for your project, don’t hesitate to reach out to us. These examples demonstrate how digital printing has opened up new possibilities for textile design and production, offering greater flexibility, customization, and creativity in the fashion industry. We’re ISO 14001:2015 Certified. Silk fabrics 3 fabrics. We’ll help you understand what goes into each process and which technique best suits your needs. Digital printing machines can print on everything from thick cardstock, heavyweight papers and folding cartons to fabric, plastics and synthetic substrates. Custom decks may be produced for myriad purposes. Customized Apparel: Customized apparel refers to clothing items that are tailored or personalized according to individual preferences, measurements, or design choices. Single people are given a nudge to bring a date by simply adding “plus guest” to the end of their name. Regarding the type of dye used, printing on fabric can be divided into. Strings come in both cotton and elastic materials in a variety of colors, thicknesses and lengths.

Order Now

How fast do you send printed fabric. There are two different types of printing services we use at WDM. Unit A Brookfields Park, Manvers Way, Manvers Rotherham S63 5DR. Perfect for small runs of 50 or less. JOIN OUR EMAIL LIST FOR OFFERS, TIPS, and MORE. The typical cost of setup fees can vary from $20 to $50 per color, and the process generally involves approximately 10 minutes for setting up a screen printing job, with the duration contingent upon the intricacy of the design and the number of colors involved. Digital printing is the process of printing digital based images directly onto a variety of media substrates. Print on demand often allows for quicker turnaround and reduced waste compared to a conventional printing process. Digital printing, as the name suggests, uses digital technology. During the mid 16th century, Portuguese traders introduced playing cards to Japan. In many of the digital printing processes, the ink doesn’t permeate the substrate but forms a thin layer on the surface that may have additional adherents added by heat or curing. For retail and franchising. Contact us at online or by calling us at 203 439 6120. This is why graduates and experienced technicians cannot enrich their knowledge about digital textile printing. During steaming, washing and finishing, all the parameters should be proper. Digital printing has a higher cost per page than more traditional offset printing methods, but this price is usually offset by avoiding the cost of all the technical steps required to make printing plates. If you’re on the fence between the two, we also offer a wide range of customizations to ensure your garments are unique. Here at BOMME STUDIO, we work with our trusted partners in LA for both screenprinting and digital printing services. Screen printing is the way to create vibrant designs yes, glitter included. Digital print is suitable to make your company logo’s details look crisp and to make small text readable. They spanned 420m2 and took 10 hours to complete. Due to its ability to preserve color vibrancy and special effects even on a large scale, it’s the go to method for high quantity orders, providing cost effectiveness that digital printing can’t match. People use this versatile method for reproducing detailed images and patterns, photographs and complicated designs. Screen prints are known for their durability and longevity, especially on suitable fabrics, but they can be prone to cracking or peeling over time with extensive wear or improper care.

Recent Comments